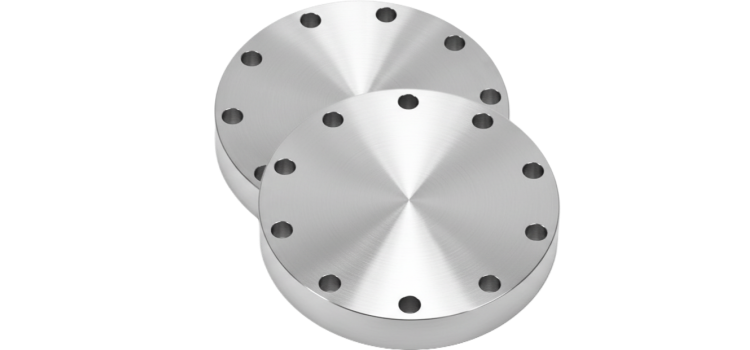

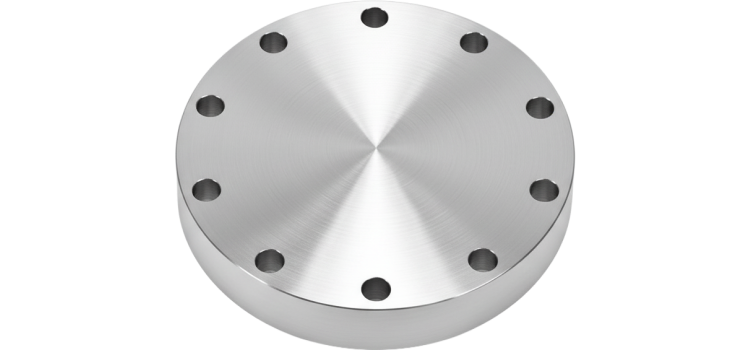

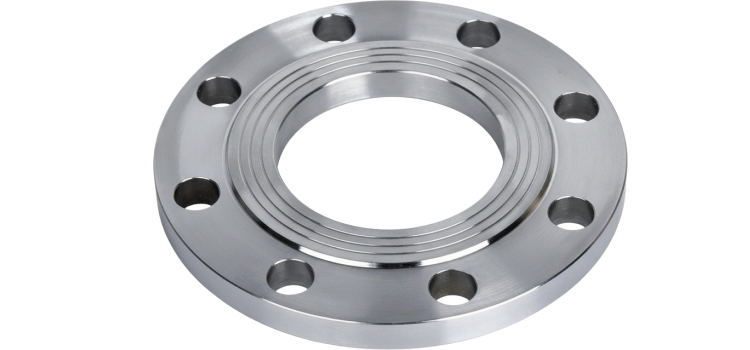

A BLIND FLANGE (BL) IS A SOLID FLANGE USED TO CLOSE THE END OF A PIPE, VALVE, OR PRESSURE VESSEL OPENING. IT HAS NO BORE AND IS BOLTED IN PLACE TO ALLOW EASY ACCESS TO THE PIPING SYSTEM FOR INSPECTION, MAINTENANCE, OR FUTURE EXPANSION. IDEAL FOR HIGH-PRESSURE APPLICATIONS, BLIND FLANGES PROVIDE A STRONG, LEAK-PROOF SEAL AND ARE COMMONLY USED IN INDUSTRIES LIKE OIL & GAS, POWER GENERATION, AND PETROCHEMICALS

Type

Solid flange with no bore.

Size Range

½” to 60” (DN15 to DN1500)

Custom sizes available on request

Pressure Class

ANSI/ASME: Class 150 / 300 / 400 / 600 / 900 / 1500 / 2500

DIN/EN: PN10 / PN16 / PN25 / PN40 / PN64

End Connections

Bolted to mating flanges with gasket seal

Compatible with RF / FF / RTJ

Body Materials

Carbon Steel (ASTM A105 / A350 LF2)

Stainless Steel (SS304 / SS316 / SS321 / Duplex)

Alloy Steel (ASTM A182 F11 / F22 / F91)

Others: Cast/Ductile Iron, Bronze, Brass, Copper, Nickel Alloys

Sealing Face Types

Raised Face (RF)

Flat Face (FF)

Ring-Type Joint (RTJ)

Tongue & Groove (T&G)

Standards

Design & Dimensions: ASME B16.5 (≤24”), ASME B16.47 (>24”), EN 1092-1, ISO 7005-1, BS 4504

Testing: API 598 / EN 12266

Applications

Pressure vessel heads, pipeline terminations, hydrostatic testing, temporary/permanent closures

Used in oil & gas, chemical, water treatment & power industries

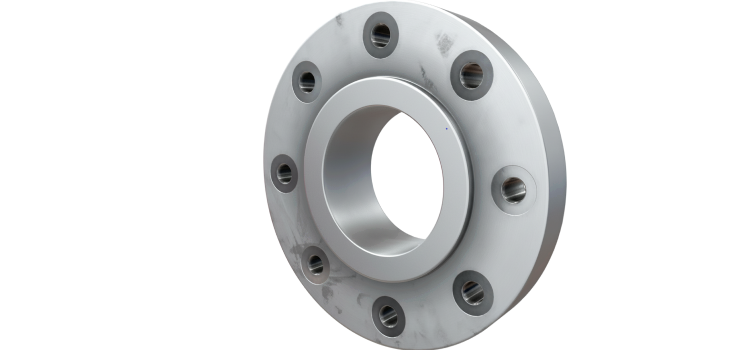

A LAP JOINT FLANGE (LJ) IS A TWO-PIECE FLANGE SYSTEM USED WITH A STUB END THAT IS WELDED TO THE PIPE. THE FLANGE I TSELF REMAINS LOOSE AND CAN ROTATE FREELY, MAKING IT I DEAL FOR FREQUENT ASSEMBLY/DISASSEMBLY AND EASY BOLT ALIGNMENT. OFTEN USED IN CORROSIVE OR HIGH MAINTENANCE ENVIRONMENTS, IT ALLOWS COST SAVINGS BY USING A CORROSION-RESISTANT STUB END AND A LOWER GRADE BACKING FLANGE

Type

Two-piece design consisting of:

• Lap Joint Flange (loose flange)

• Stub End (butt-welded to the pipe)

Flange rotates freely around the stub end – ideal for frequent dismantling, alignment, or space adjustments.

Size Range

½” to 24” (DN15 to DN600)

Custom sizes available on request

Cost-effective for larger diameters

Pressure Class

ANSI/ASME: Class 150 / 300 / 600

DIN/EN: PN10 / PN16 / PN25 / PN40

Generally suited for low to moderate pressure

End Connections

Requires stub end (butt-welded to pipe)

Rotating flange allows easy bolt alignment

Sealed with gasket between mating faces

Body Materials

Carbon Steel (ASTM A105 / A36)

Stainless Steel (SS304 / SS316)

Aluminum, Nickel Alloys & other non-corrosive materials

Sealing Face Types

Typically Flat Face (FF)

Also available in Raised Face (RF)

Seal is made on stub end face, not the flange

Standards

Design & Dimensions: ASME B16.5 (≤24”), EN 1092-1, ISO 7005-1, BS 4504

Testing: API 598, EN 12266

Materials & Welding: ASTM Standards, ASME Sec IX (stub end welding)

Applications

Systems requiring frequent dismantling or inspection

Corrosive media (SS stub ends with CS flanges)

Food processing, pharmaceuticals, shipbuilding, chemicals

Large diameter / costly piping materials for cost reduction

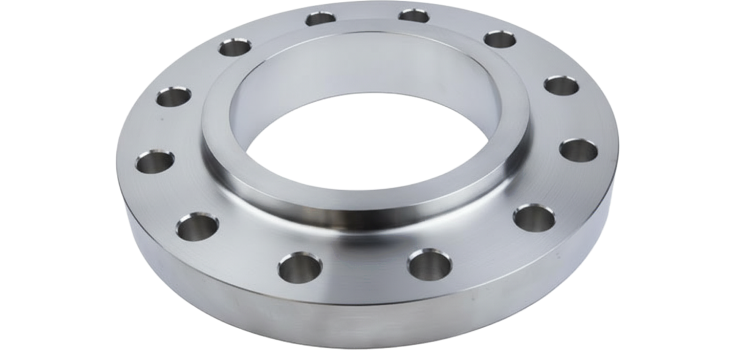

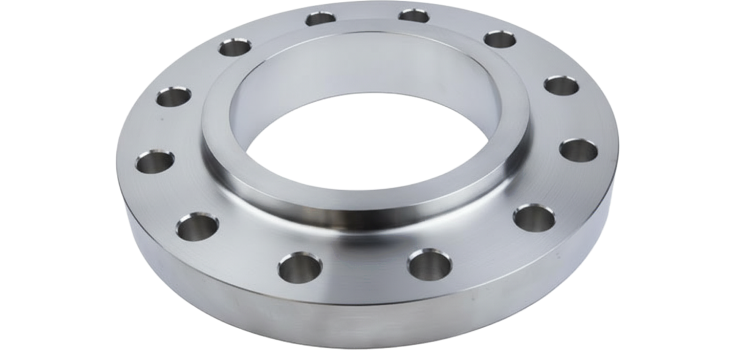

A WELD NECK FLANGE (WN) IS A HIGH-STRENGTH FLANGE DESIGNED WITH A LONG TAPERED HUB THAT IS BUTT-WELDED TO A PIPE. IT PROVIDES EXCELLENT STRESS DISTRIBUTION AND IS IDEAL FOR HIGH-PRESSURE, HIGH-TEMPERATURE, AND CRITICAL APPLICATIONS. COMMONLY USED IN OIL & GAS, POWER PLANTS, AND PETROCHEMICAL INDUSTRIES, IT ENSURES A SECURE, LEAK-PROOF CONNECTION AND MINIMIZES TURBULENCE AND EROSION AT THE JOINT.

Type

Long tapered hub with butt-welded connection

Designed for high-pressure & high-temperature applications

Ideal for critical services and vibration-prone systems

Size Range

½” to 60” (DN15 to DN1500)

Custom sizes available for special applications

Pressure Class

ANSI/ASME: Class 150 / 300 / 400 / 600 / 900 / 1500 / 2500

DIN/EN: PN10 / PN16 / PN25 / PN40 / PN64

Suitable for high-pressure systems (material & schedule dependent)

End Connections

Butt weld end integral to flange design

Matches pipe schedule for seamless welding

Machined to match pipe bore for smooth flow & reduced turbulence

Body Materials

Carbon Steel (ASTM A105 / A350 LF2)

Stainless Steel (SS304 / SS316 / SS321 / Duplex)

Alloy Steel (ASTM A182 F11 / F22 / F91)

Nickel Alloys, Copper Alloys, Titanium (per service needs)

Sealing Face Types

Raised Face (RF)

Ring-Type Joint (RTJ)

Flat Face (FF)

Male-Female (M/F)

Tongue & Groove (T&G)

Standards

Design & Dimensions: ASME B16.5 (≤24”), ASME B16.47 (>24”), EN 1092-1, ISO 7005-1, BS 4504

Testing: API 598, EN 12266, MSS SP-44

Materials & Welding: ASTM specifications, ASME Section IX (welding)

Applications

Oil & Gas, Petrochemical, Power Generation

High-pressure steam lines, Offshore platforms

Cryogenic & high-temperature services

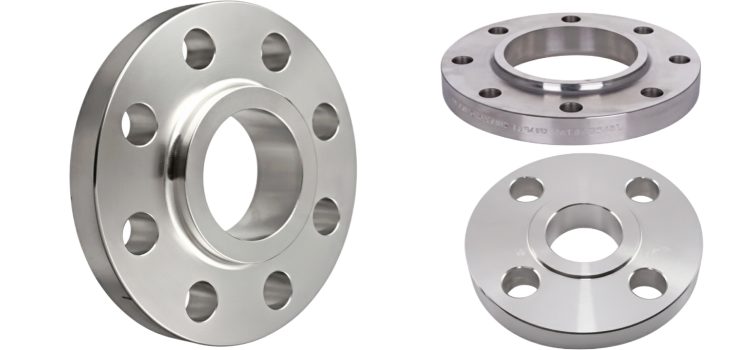

A SLIP-ON FLANGE (SO) IS A FLANGE THAT SLIDES OVER THE PIPE AND IS FILLET-WELDED ON BOTH THE INSIDE AND OUTSIDE TO PROVIDE STRENGTH AND PREVENT LEAKAGE. IT IS EASY TO ALIGN AND INSTALL, MAKING IT IDEAL FOR LOW- TO MEDIUM-PRESSURE APPLICATIONS. COMMONLY USED IN WATER, HVAC, AND INDUSTRIAL SYSTEMS, SLIP-ON FLANGES ARE COST-EFFECTIVE AND SUITABLE WHERE WELDING PRECISION IS LESS CRITICAL.

Type

Slides over the pipe and fillet-welded on both inner & outer edges

No tapered hub – flat face rests on the pipe

Easier alignment than weld neck flanges

Suitable for low to medium pressure, non-critical applications

Size Range

½” to 48” (DN15 to DN1200)

Custom sizes available on request

Pressure Class

ANSI/ASME: Class 150 / 300 / 400 / 600

DIN/EN: PN10 / PN16 / PN25 / PN40

Typically used in moderate pressure & temperature conditions

End Connections

Designed to be welded onto pipe ends

Matches pipe OD, not ID (requires accurate fitment)

Not suitable for beveled butt welds

Body Materials

Carbon Steel (ASTM A105 / A350 LF2)

Stainless Steel (SS304 / SS316 / SS321 / Duplex)

Alloy Steel (ASTM A182 F11 / F22)

Other Alloys: Copper, Nickel, Cast Iron, Ductile Iron, etc.

Sealing Face Types

Raised Face (RF)

Flat Face (FF)

Ring-Type Joint (RTJ) – less common for SO

Standards

Design & Dimensions: ASME B16.5 (≤24”), EN 1092-1, BS 4504, ISO 7005-1

Testing: API 598, EN 12266

Materials & Welding: ASTM specifications, ASME Section IX

Applications

Water & wastewater systems

Fire protection systems

HVAC & general industrial piping

Non-critical oil & gas or chemical systems

Ideal for frequent disassembly & cost-effective installation

A SOCKET WELD FLANGE (SW) IS DESIGNED FOR SMALL DIAMETER, HIGH-PRESSURE PIPING SYSTEMS. IT FEATURES A RECESSED SOCKET INTO WHICH THE PIPE IS INSERTED AND FILLET-WELDED AROUND THE OUTER EDGE. THIS DESIGN PROVIDES A STRONG, LEAK-RESISTANT JOINT WITH SMOOTH FLOW CHARACTERISTICS. COMMONLY USED IN STEAM, HYDRAULIC, AND CHEMICAL SYSTEMS, SOCKET WELD FLANGES ARE IDEAL WHERE SPACE IS LIMITED AND HIGH INTEGRITY IS REQUIRED.

Type

Features a recessed socket for pipe insertion

Fillet-welded only on the outer side

Provides smooth bore & good flow characteristics

Suitable for small-bore, high-pressure piping systems

Size Range

½” to 4” (DN15 to DN100)

Typically for small-diameter pipes

Custom sizes available on request

Pressure Class

ANSI/ASME: Class 150 / 300 / 600 / 900 / 1500

DIN/EN: PN10 / PN16 / PN25 / PN40

Suitable for moderate to high pressure & temperature

End Connections

Socket weld connection

Pipe inserted into socket & fillet welded externally

Strong, leak-proof joint for small sizes

Not recommended for cyclic or dynamic loading

Body Materials

Carbon Steel (ASTM A105 / A350 LF2)

Stainless Steel (SS304 / SS316 / SS321 / Duplex)

Alloy Steel (ASTM A182 F11 / F22)

Other materials: Brass, Bronze, Copper Alloys, Nickel Alloys (on request)

Sealing Face Types

Raised Face (RF)

Flat Face (FF)

Ring-Type Joint (RTJ)

Standards

Design & Dimensions: ASME B16.5 (≤24”), EN 1092-1, ISO 7005-1, BS 4504

Testing: API 598, EN 12266

Materials & Welding: ASTM specifications, ASME Section IX

Applications

High-pressure steam systems

Chemical & petrochemical plants

Power generation

Hydraulic & compressed air systems

Ideal for small pipe sizes in high-integrity services

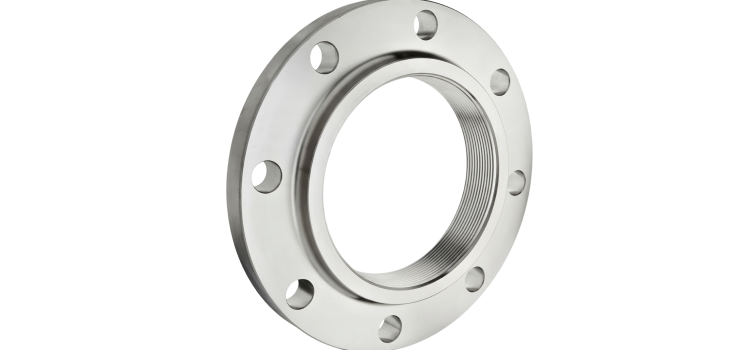

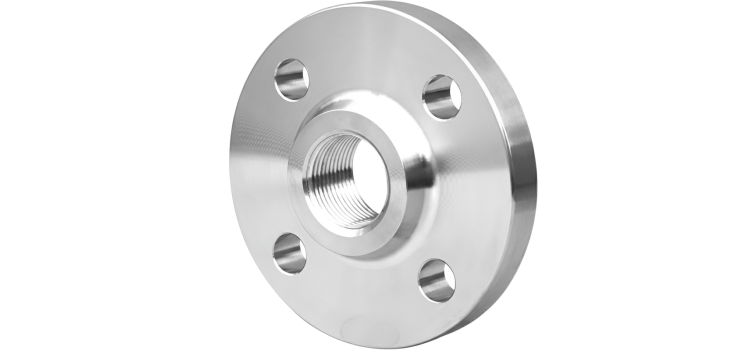

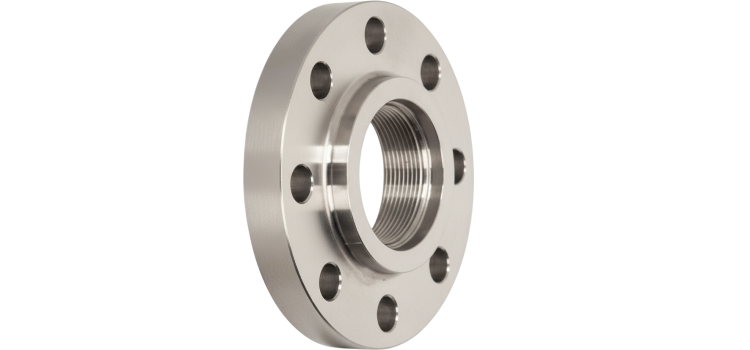

A THREADED FLANGE (ALSO KNOWN AS A SCREWED FLANGE OR SCRD FLANGE) IS DESIGNED WITH INTERNAL THREADS THAT ALLOW IT TO BE SCREWED DIRECTLY ONTO A PIPE WITHOUT THE NEED FOR WELDING. IT IS IDEAL FOR LOW-PRESSURE AND NON-CRITICAL APPLICATIONS, ESPECIALLY IN FLAMMABLE OR EXPLOSIVE ENVIRONMENTS WHERE WELDING IS HAZARDOUS. COMMONLY USED IN FUEL LINES, COMPRESSED AIR SYSTEMS, AND UTILITY PIPING.

Type

Internal threads allow flange to be screwed onto pipe without welding

Commonly used in low-pressure, non-critical applications

Ideal for flammable or explosive environments where welding is unsafe

Also known as Screwed Flange (SCRD)

Size Range

½” to 4” (DN15 to DN100)

Custom sizes available on request

Pressure Class

ANSI/ASME: Class 150 / 300 / 600

DIN/EN: PN10 / PN16 / PN25

Typically used in low to moderate pressure systems

End Connections

Threaded (screwed) connection – no welding required

Standard threads: NPT (ASME B1.20.1) or BSP (ISO 7-1 / EN 10226)

Optional seal weld can be applied for added strength & leak protection

Body Materials

Carbon Steel (ASTM A105 / A350 LF2)

Stainless Steel (SS304 / SS316 / SS321)

Alloy Steel (ASTM A182 F11 / F22)

Others: Brass, Bronze, Copper Alloys, PVC, Gunmetal (special applications)

Sealing Face Types

Raised Face (RF)

Flat Face (FF)

Ring-Type Joint (RTJ) – less common

Standards

Design & Dimensions: ASME B16.5 (≤24”), EN 1092-1, ISO 7005-1, BS 4504

Thread Standards: ASME B1.20.1 (NPT), ISO 7-1 / EN 10226 (BSPT/BSPP)

Testing: API 598, EN 12266

Applications

Low-pressure systems

Fuel, gas & explosive environments

Compressed air & instrumentation lines

Plumbing & utility services

Temporary or easily disassembled piping systems

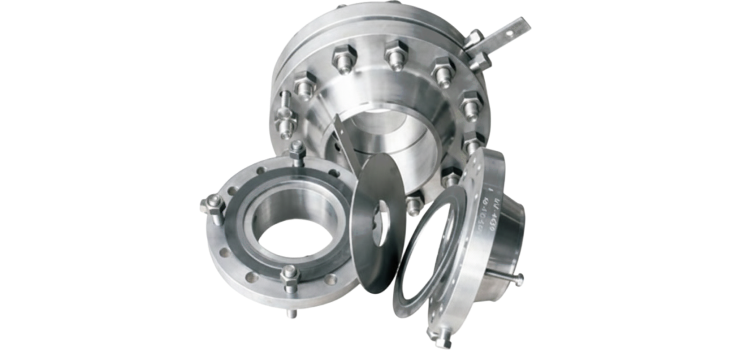

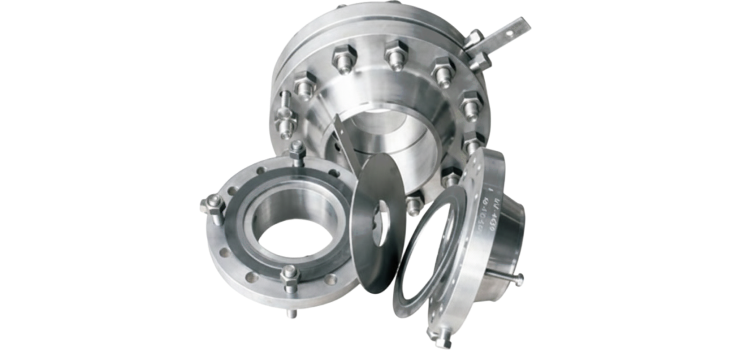

AN ORIFICE FLANGE IS A SPECIALIZED FLANGE USED FOR FLOW MEASUREMENT IN PIPELINES. IT IS DESIGNED TO HOLD AN ORIFICE PLATE AND INCLUDES PRESSURE TAP HOLES TO MEASURE DIFFERENTIAL PRESSURE ACROSS THE PLATE. COMMONLY USED IN OIL & GAS, CHEMICAL, AND UTILITY SYSTEMS, IT PROVIDES ACCURATE FLOW MONITORING AND IS BUILT TO WITHSTAND HIGH-PRESSURE ENVIRONMENTS. ORIFICE FLANGES ARE MANUFACTURED PER ASME B16.36 AND ARE COMPATIBLE WITH STANDARD PIPING FLANGES

Type

Specialized flange assembly used with an orifice plate to measure fluid flow rate in pipelines

Supplied as a pair of flanges with:

– Pressure tap holes (for differential pressure measurement)

– Jack screws (to separate flanges for plate removal)

Used with flow meters or transmitters

Size Range

1” to 24” (DN25 to DN600)

Custom sizes available for larger/specialty applications

Matches piping and flow equipment sizes

Pressure Class

ANSI/ASME: Class 150, 300, 600, 900, 1500, 2500

DIN/EN: PN10, PN16, PN25, PN40, PN64

Must match system and process conditions

End Connections

Typically flanged – compatible with weld neck or slip-on types

Bolted to standard pipe flanges or fittings

Includes tapped ports (¼” NPT or similar) for pressure instruments

Body Materials

Carbon Steel: ASTM A105, A350 LF2

Stainless Steel: SS304 / SS316 / Duplex

Alloy Steel: ASTM A182 F11 / F22

Other materials (Hastelloy, Monel, etc.) available for specific media

Sealing Face Types

Raised Face (RF)

Ring-Type Joint (RTJ) – common in high-pressure services

Gasket type selected per application and pressure rating

Standards

Design & Dimensions: ASME B16.36 (Orifice Flanges), ASME B16.5, ASME B16.47, EN 1092-1

Testing: API 598 (pressure), EN 12266 (leak testing)

Measurement: ISO 5167 (orifice flow measurement)

Applications

Flow measurement of gases, steam, or liquids

Used in oil & gas, chemical plants, power generation, water treatment

Installed with orifice plates and differential pressure transmitters

Suitable for clean and moderately dirty process fluids

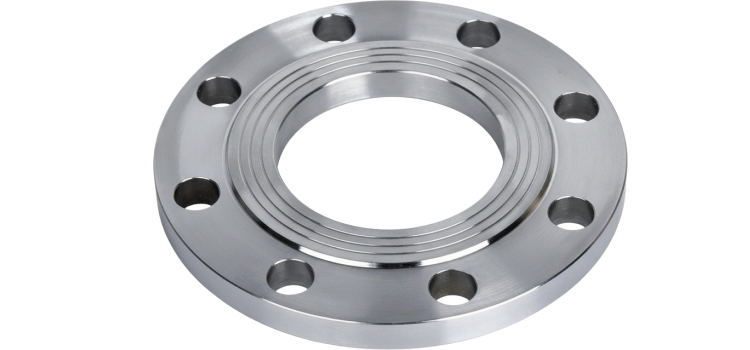

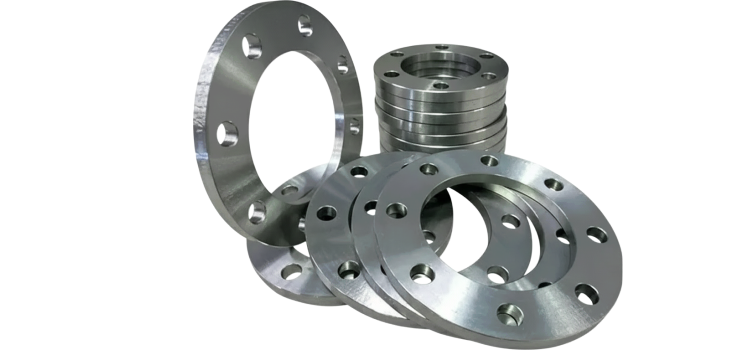

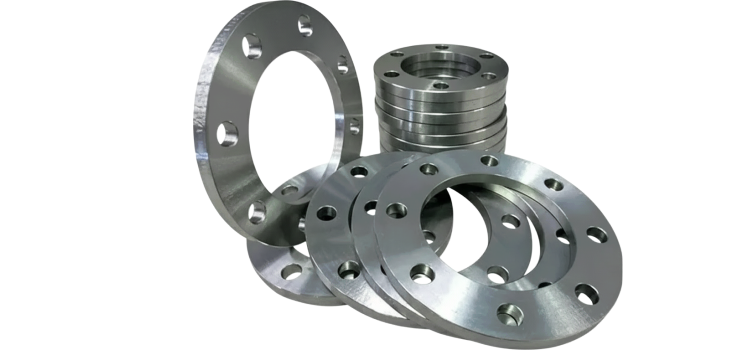

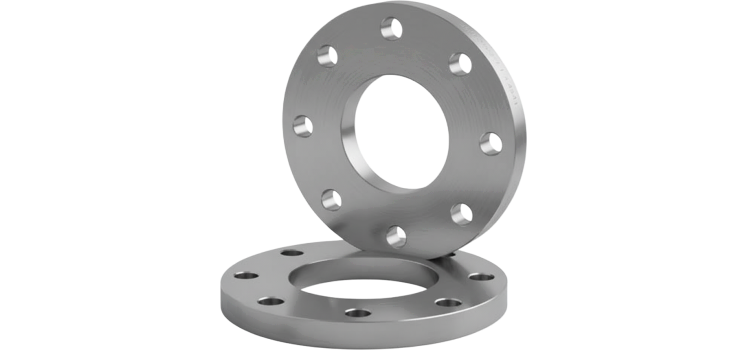

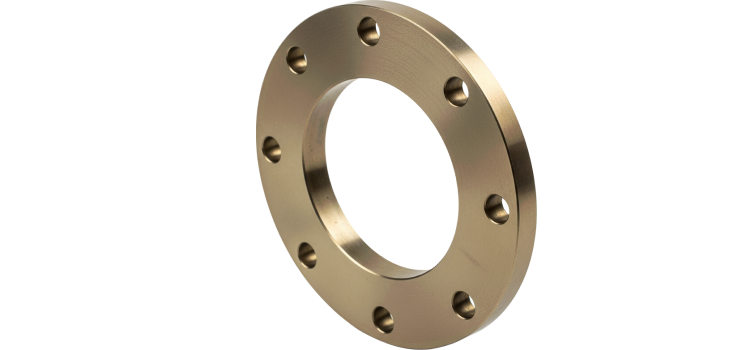

A PLATE FLANGE IS A SIMPLE, FLAT FLANGE MADE FROM A SINGLE METAL PLATE, USED TO CONNECT PIPES OR EQUIPMENT I N LOW-PRESSURE PIPING SYSTEMS. IT IS FILLET-WELDED DIRECTLY TO THE PIPE AND FEATURES BOLT HOLES FOR SECURE FASTENING. DUE TO ITS COST-EFFECTIVENESS AND EASE OF FABRICATION, PLATE FLANGES ARE WIDELY USED IN WATER SUPPLY, HVAC, FIRE PROTECTION, AND GENERAL INDUSTRIAL SERVICES WHERE HIGH PRESSURE AND TEMPERATURE ARE NOT A CONCERN.

Type

Flat, circular disc with bolt holes around the perimeter and a central bore

Made from a single metal plate, without a hub or taper

Welded directly to the pipe (typically fillet weld)

Economical and simple design, suited for low-pressure, non-critical applications

Size Range

½” to 48” (DN15 to DN1200)

Custom sizes available

Widely used in light-duty and general-purpose piping systems

Pressure Class

ANSI/ASME: Class 150, 300 (typically up to 300)

DIN/EN: PN6, PN10, PN16, PN25

Not recommended for high-pressure or high-temperature services

End Connections

Welded (fillet weld to pipe’s outer surface)

Easy to fabricate and install

No beveling required (unlike weld neck flanges)

Body Materials

Carbon Steel: ASTM A105, A36

Stainless Steel: SS304 / SS316

Mild steel, galvanized steel, alloy steel

Also available in aluminum, bronze, cast iron for specific industries

Sealing Face Types

Flat Face (FF) – most common

Raised Face (RF) – less typical for plate flanges

Standards

Design & Dimensions: EN 1092-1 Type 01 (Plate Flange – Plain), ASME B16.5 (rare), BS 4504, ISO 7005-1

Testing: EN 12266, API 598 (system pressure testing)

Applications

Low-pressure water pipelines

Fire protection systems

General industrial or structural piping

HVAC, irrigation, utility networks

Common in non-critical and cost-sensitive projects