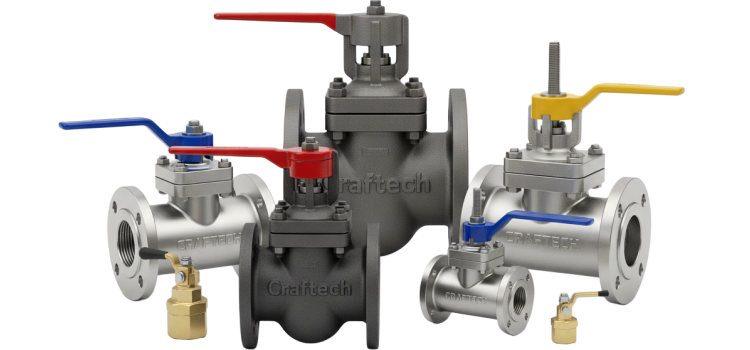

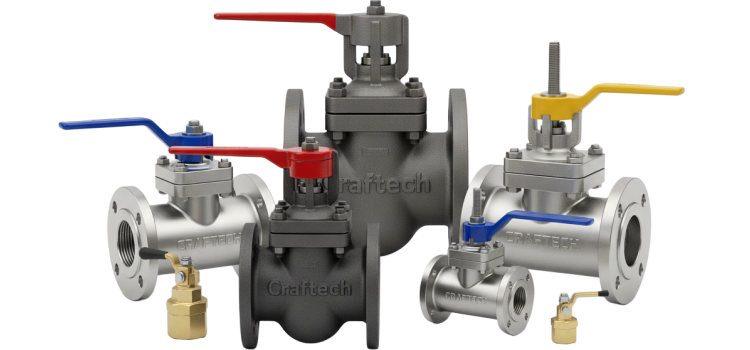

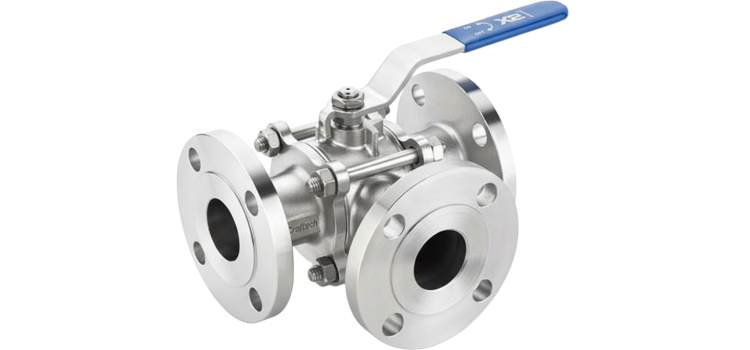

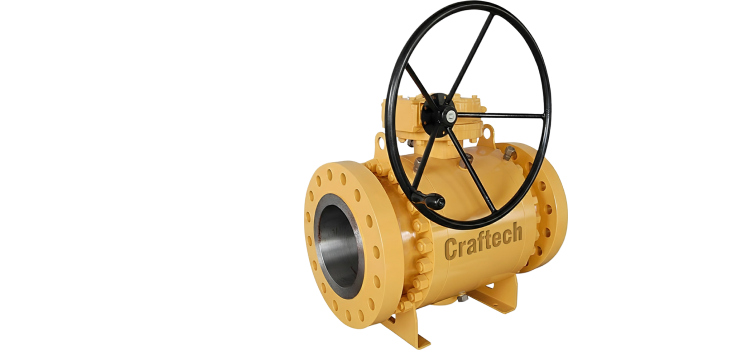

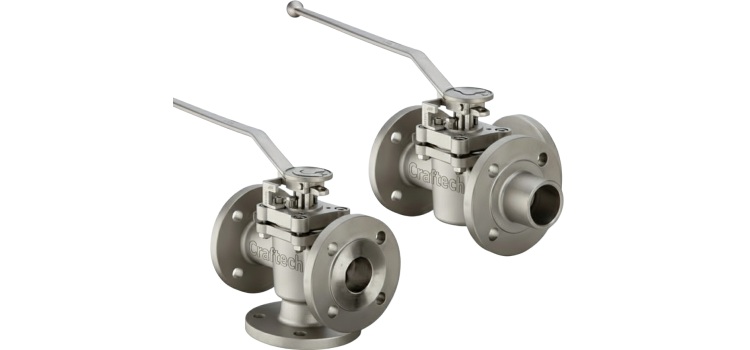

USED FOR QUICK ON/OFF CONTROL OF FLUID FLOW IN PIPELINES WIDELY USED IN OIL AND GAS, CHEMICAL, WATER TREATMENT, HVAC, AND MARINE INDUSTRIES HANDLES LIQUIDS, GASES, STEAM, AND SLURRIES EFFECTIVELY PROVIDES TIGHT SHUT-OFF WITH MINIMAL TORQUE AND EASY OPERATION I DEAL FOR APPLICATIONS REQUIRING FULL BORE AND LOW-PRESSURE DROP SUITABLE FOR HIGH-PRESSURE, HIGH-TEMPERATURE, AND CORROSIVE ENVIRONMENTS COMMON IN INDUSTRIAL PLANTS, PROCESS SYSTEMS, AND UTILITY SERVICES

Type

Full Port / Reduced Port

Floating Ball / Trunnion Mounted

Two-piece

/ Three-piece / One-piece

Size Range

¼” to 12” (DN6 to DN300)

Pressure Class

ANSI Class 150 / 300 / 600

PN16 / PN25 / PN40

End Connections

Threaded (NPT/BSP)

Flanged (ANSI, DIN, JIS)

Socket Weld / Butt Weld

Body Materials

Stainless Steel (SS304 / SS316)

Carbon Steel (WCB)

Brass / Bronze

Ball & Seat Materials

Stainless Steel / Chrome Plated

PTFE / RPTFE / PEEK

Standards

Design: API 6D / ISO 17292 / ASME B16.34

Testing: API 598 / EN 12266

Flanges: ASME B16.5 / EN 1092-1

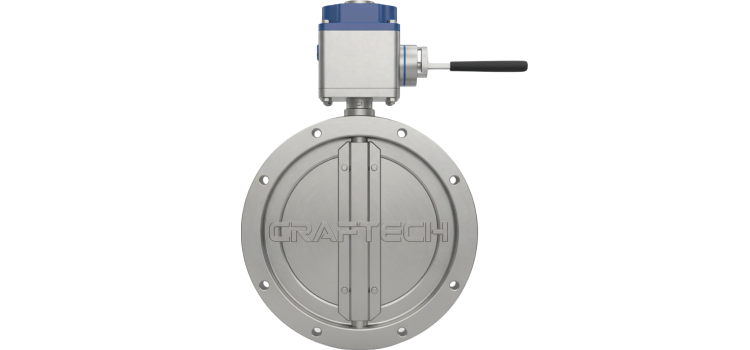

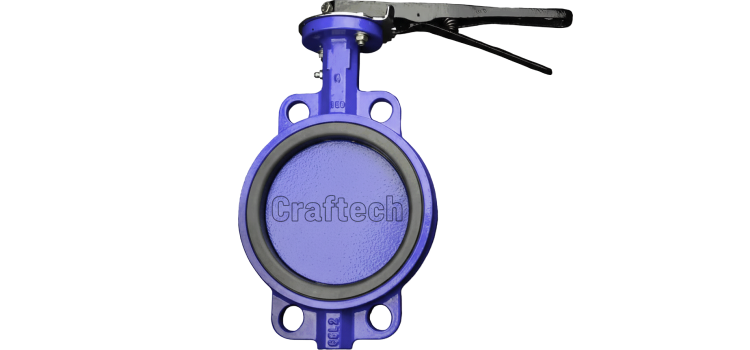

USED FOR ISOLATING OR REGULATING FLOW IN LARGE-DIAMETER PIPELINES COMMON IN WATER DISTRIBUTION, WASTEWATER TREATMENT, HVAC, FIRE PROTECTION, AND MARINE SYSTEMS SUITABLE FOR LIQUIDS, GASES, AND SLURRIES I DEAL FOR LOW-PRESSURE, LOW-TORQUE, AND SPACE-CONSTRAINED APPLICATIONS PREFERRED IN SYSTEMS REQUIRING QUICK OPERATION AND LIGHTWEIGHT VALVES WIDELY USED IN POWER PLANTS, CHEMICAL INDUSTRIES, AND PROCESS SYSTEMS NOT SUITABLE FOR HIGH-PRESSURE THROTTLING IN ABRASIVE SERVICES

Type

WAFER / LUG / DOUBLE FLANGED / UTYPE

CONCENTRIC / DOUBLE OFFSET /

TRIPLE OFFSET

Size Range

2” TO 72” (DN50 TO DN1800)

Pressure Class

ANSI CLASS 150 / 300

PN10 / PN16 / PN25

End Connections

WAFER / LUG / FLANGED / BUTT WELD

Body Materials

CAST IRON / DUCTILE IRON

Carbon Steel (WCB)

STAINLESS STEEL (SS304

/ SS316)

ALUMINUM BRONZE

Seat Materials

EPDM / NBR / PTFE / VITON

METAL SEATED

Standards

Design: API 609 / ISO 5752 / EN 593

Testing: API 598 / EN 12266

Flanges: ASME B16.5 / EN 1092-1

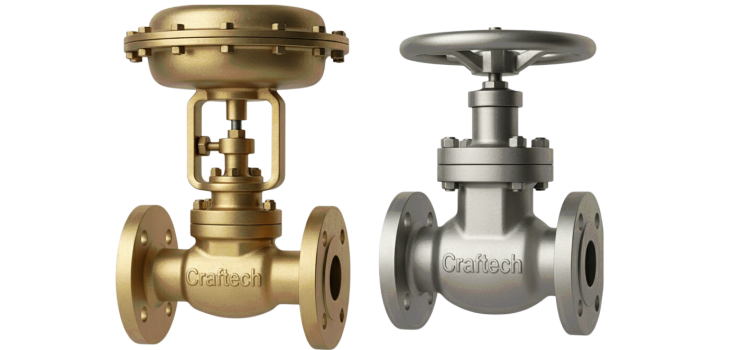

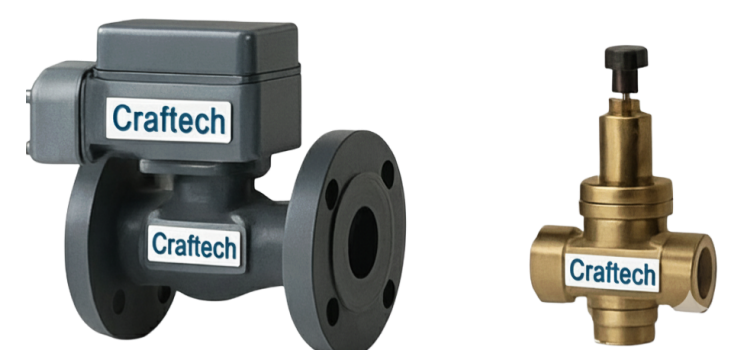

USED FOR PRECISE REGULATION OF FLOW, PRESSURE, TEMPERATURE, OR LEVEL IN PROCESS SYSTEMS COMMON IN OIL & GAS, POWER PLANTS, CHEMICAL PROCESSING, AND WATER TREATMENT I DEAL FOR MODULATING CONTROL IN AUTOMATED SYSTEMS SUITABLE FOR LIQUIDS, GASES, STEAM, AND SLURRIES USED IN HVAC, PHARMACEUTICAL, FOOD PROCESSING, AND PULP & PAPER INDUSTRIES CRITICAL FOR MAINTAINING PROCESS STABILITY AND SYSTEM EFFICIENCY NOT USED FOR SIMPLE ON/OFF ISOLATION

TYPE

GLOBE / ANGLE / BUTTERFLY

BALL / DIAPHRAGM

PNEUMATIC / ELECTRIC

/ HYDRAULIC ACTUATED

LINEAR / ROTARY MOTION

SIZE RANGE

½” TO 24” (DN15 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

FLANGED / THREADED / SOCKET WELD / BUTT WELD

BODY MATERIALS

CARBON STEEL (WCB)

STAINLESS STEEL (SS304 / SS316)

CAST IRON /

BRONZE / ALLOY STEELS

TRIM MATERIALS

STAINLESS STEEL / HARDENED ALLOYS

SOFT OR METAL SEATS (PTFE, RPTFE,

PEEK, ETC.)

STANDARDS

DESIGN: IEC 60534 / ANSI/ISA 74

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

ACTUATION

PNEUMATIC DIAPHRAGM / ELECTRIC

MOTOR POSITIONER / ELECTRO-PNEUMATIC

CONTROL FEATURES

MODULATING OR ON/OFF CONTROL

FLOW, PRESSURE, TEMPERATURE, AND LEVEL REGULATION

AVAILABLE WITH POSITIONERS, I/P CONVERTERS, AND FEEDBACK SYSTEMS

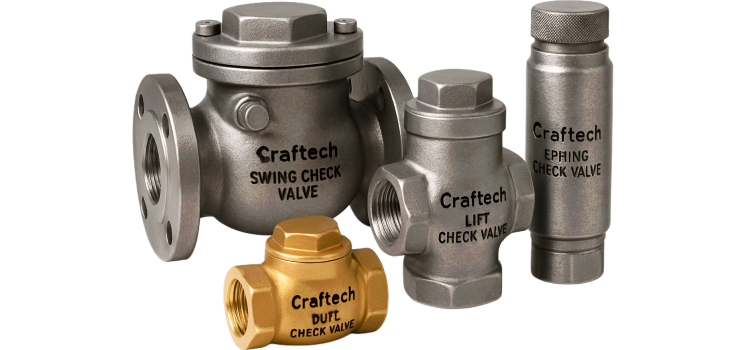

USED TO PREVENT BACKFLOW IN PIPELINES COMMON IN WATER, WASTEWATER, OIL & GAS, AND CHEMICAL SYSTEMS PROTECTS PUMPS, COMPRESSORS, AND EQUIPMENT FROM REVERSE FLOW SUITABLE FOR LIQUIDS, GASES, STEAM, AND SLURRIES WIDELY USED IN POWER PLANTS, HVAC, MARINE, AND FIRE PROTECTION SYSTEMS OPERATES AUTOMATICALLY WITHOUT EXTERNAL CONTROL NOT SUITABLE FOR THROTTLING OR FLOW REGULATION

TYPE

SWING / LIFT / WAFER

DUAL PLATE / TILTING DISC / BALL TYPE

SILENT

(SPRING-LOADED) / NON-SLAM TYPE

SIZE RANGE

½” TO 36” (DN15 TO DN900)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

FLANGED / WAFER / LUG / THREADED

FLANGED / WAFER / LUG / THREADED

BODY MATERIALS

CAST IRON / DUCTILE IRON

CARBON STEEL (WCB)

STAINLESS STEEL (SS304

/ SS316)

BRONZE / ALLOY STEELS

DISC / INTERNALS

STAINLESS STEEL / BRONZE / RUBBER COATED / SPRING-LOADED OPTIONS

METAL-TO-METAL OR SOFT SEATED (NBR, EPDM, PTFE)

STANDARDS

DESIGN: API 6D / BS 1868 / ASME B16.34 / EN 12334

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

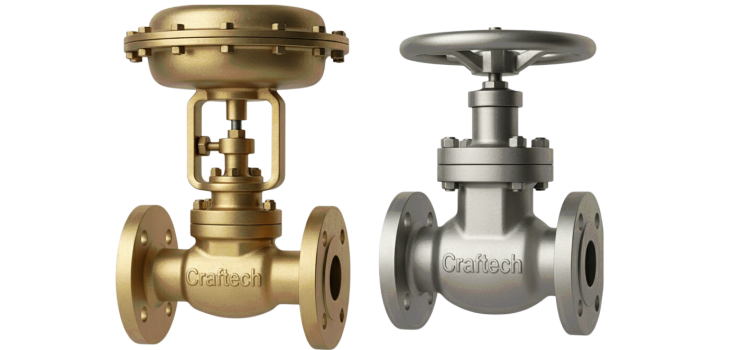

IDEAL FOR THROTTLING AND REGULATING FLOW IN PIPELINES; COMMONLY USED IN WATER SYSTEMS, STEAM, OIL, AND GAS INDUSTRIES REQUIRING PRECISE FLOW CONTROL.

TYPE

SWING / LIFT / WAFER

DUAL PLATE / TILTING DISC / BALL TYPE

SILENT

(SPRING-LOADED) / NON-SLAM TYPE

SIZE RANGE

½” TO 24” (DN15 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

900 / 1500

END CONNECTIONS

FLANGED / THREADED / BUTT WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

CARBON STEEL (WCB)

STAINLESS STEEL (SS304

/ SS316)

BRONZE / ALLOY STEELS

DISC / INTERNALS

STAINLESS STEEL / BRONZE / RUBBER COATED / SPRING-LOADED OPTIONS

METAL-TO-METAL OR SOFT SEATED (NBR, EPDM, PTFE)

STANDARDS

DESIGN: API 6D / BS 1868 / ASME B16.34 / EN 12334

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

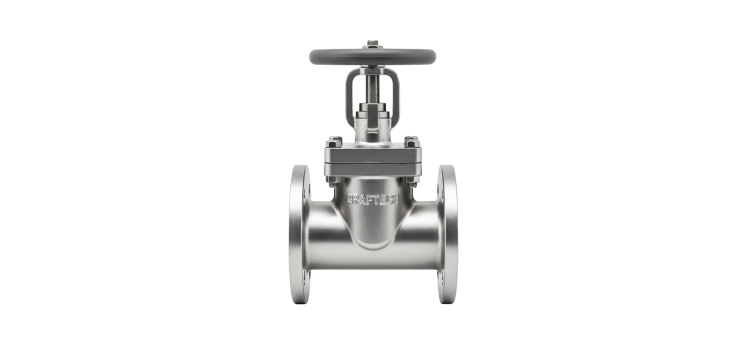

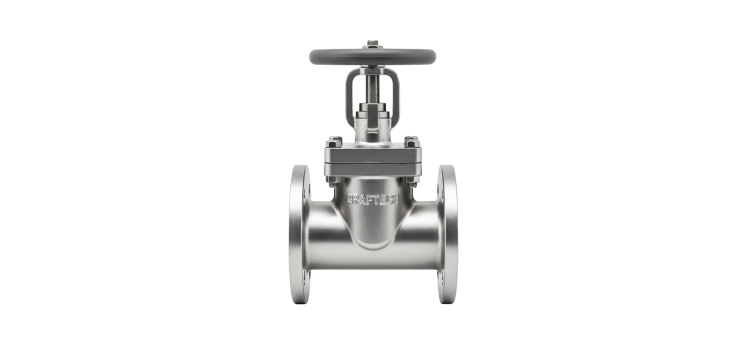

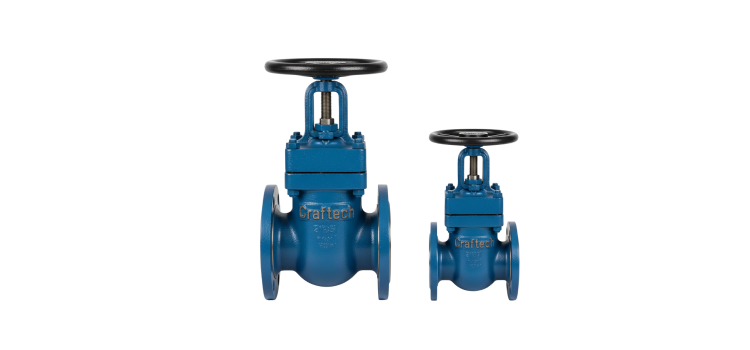

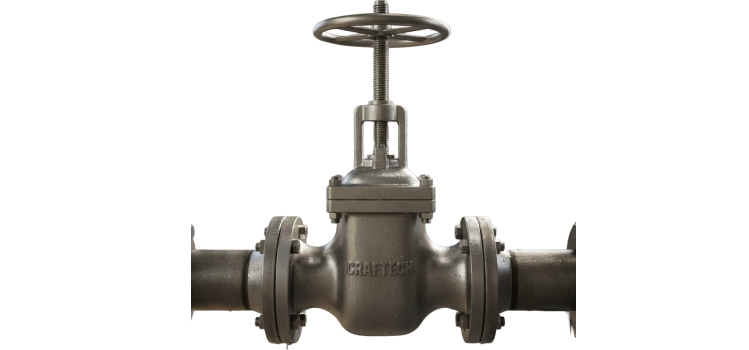

USED MAINLY FOR ON/OFF ISOLATION OF FLUID FLOW IN PIPELINES COMMON IN OIL AND GAS, WATER TREATMENT, CHEMICAL PROCESSING, POWER GENERATION, AND MINING INDUSTRIES SUITABLE FOR LIQUIDS, GASES, STEAM, AND SLURRIES IDEAL FOR FULL FLOW WITH MINIMAL PRESSURE LOSS USED IN HIGH-PRESSURE AND HIGH-TEMPERATURE SYSTEMS FOUND IN WATER SUPPLY, WASTEWATER MANAGEMENT, INDUSTRIAL PLANTS, AND MARINE APPLICATIONS NOT RECOMMENDED FOR FLOW REGULATION OR THROTTLING

TYPE

SWING / LIFT / WAFER

DUAL PLATE / TILTING DISC / BALL TYPE

SILENT

(SPRING-LOADED) / NON-SLAM TYPE

SIZE RANGE

½” TO 24” (DN15 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

900 / 1500

END CONNECTIONS

FLANGED / THREADED / BUTT WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

CARBON STEEL (WCB)

STAINLESS STEEL (SS304

/ SS316)

BRONZE / ALLOY STEELS

DISC / INTERNALS

STAINLESS STEEL / BRONZE / RUBBER COATED / SPRING-LOADED OPTIONS

METAL-TO-METAL OR SOFT SEATED (NBR, EPDM, PTFE)

STANDARDS

DESIGN: API 6D / BS 1868 / ASME B16.34 / EN 12334

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

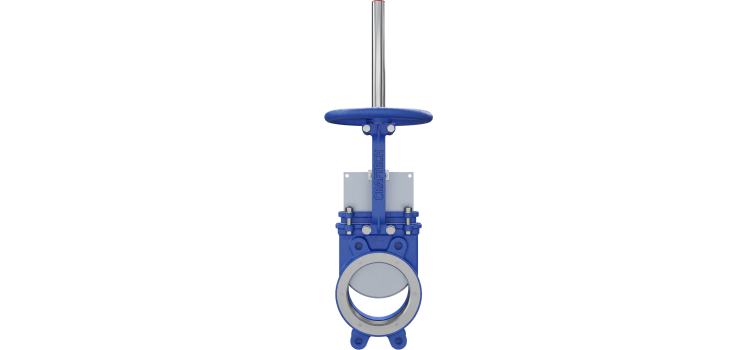

USED FOR ON/OFF CONTROL IN SLURRY, VISCOUS, AND ABRASIVE MEDIA COMMON IN MINING, WASTEWATER, PULP & PAPER, AND CHEMICAL INDUSTRIES I DEAL FOR SOLIDS, SLURRY, AND BULK MATERIAL HANDLING NOT SUITABLE FOR HIGH-PRESSURE OR THROTTLING APPLICATIONS

TYPE

UNI-DIRECTIONAL / BI-DIRECTIONAL

MANUAL / PNEUMATIC / ELECTRIC /

HYDRAULIC ACTUATION

RISING / NON-RISING STEM

SIZE RANGE

2” TO 48” (DN50 TO DN1200)

PRESSURE CLASS

PN10 / PN16

CUSTOM RATING

END CONNECTIONS

WAFER / LUG / FLANGED / BUTT WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

CARBON STEEL (WCB)

STAINLESS STEEL (SS304 / SS316)

GATE & SHEET MATERIALS

STAINLESS STEEL (SS304 / SS316)

HARD-FACED OR PTFE-COATED OPTIONS

METAL-TO-METAL / EPDM / PTFE / NBR / VITION

STANDARDS

DESIGN: MSS SP-81

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

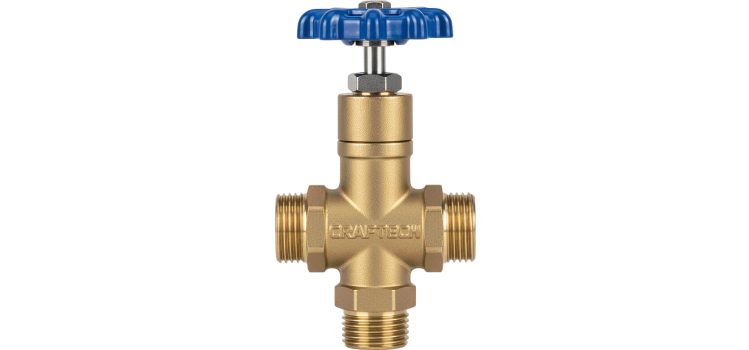

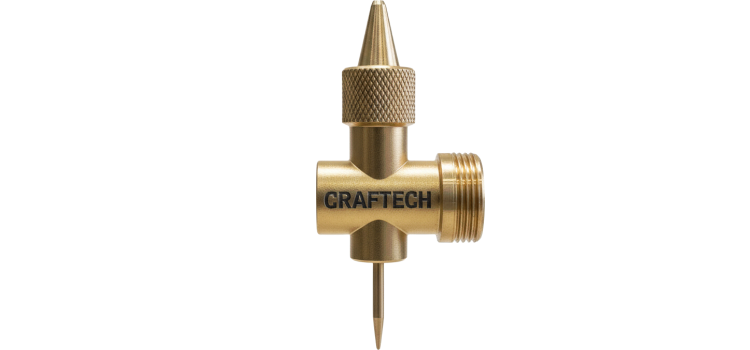

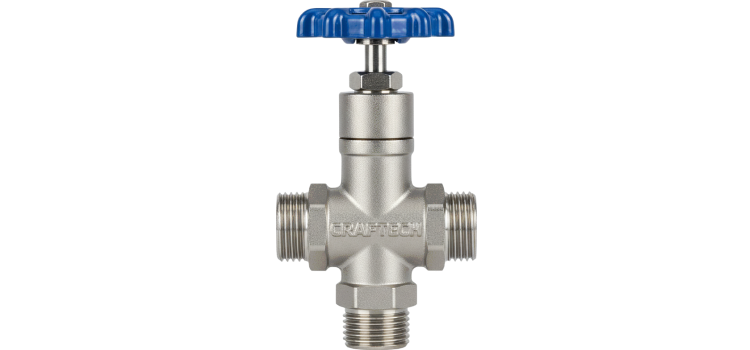

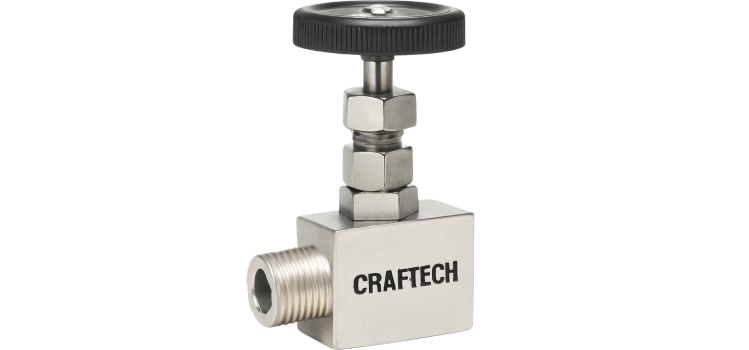

USED FOR PRECISE FLOW CONTROL IN LOW FLOW APPLICATIONS COMMON IN INSTRUMENTATION, SAMPLING, AND PRESSURE REGULATION I DEAL FOR OIL & GAS, CHEMICAL, AND LABORATORY SYSTEMS NOT SUITABLE FOR HIGH-FLOW OR QUICK SHUT-OFF NEEDS

TYPE

STRAIGHT / ANGLE / FORGED / BAR STOCK

I NTEGRAL BONNET / UNION BONNET

MANUAL / PANEL / MOUNT / INSTRUMENTATION

SIZE RANGE

1 /8” TO 2” (DN6 TO DN50)

PRESSURE CLASS

6000+ PSI (414+ BAR)

END CONNECTIONS

THREADED (NPT, BSP)

COMPRESSION TUBE FITTINGS

SOCKET WELD / BUTT WELD

BODY MATERIALS

STAINLESS STEEL (SS304 / SS316)

BRASS / CARBON STEEL

ALLOY 400 / HASTELLOY / DUPLEX STEEL

SEAT & TIP MATERIALS

METAL-TO-METAL / SOFT SEAT (PTFE, PEEK)

REGULATING OR SHUT-OFF TIP

STANDARDS

DESIGN: ASME B16.34 / API 598 (TESTING)

THREADS: ASME B1.20.1 (NPT) / ISO 7-1( BSP)

USED TO PREVENT BACKFLOW IN PIPELINES PROTECTS PUMPS AND EQUIPMENT FROM REVERSE FLOW COMMON IN WATER, OIL, GAS, STEAM, AND CHEMICAL SYSTEMS OPERATES AUTOMATICALLY, NO MANUAL CONTROL NEEDED

TYPE

SWING / LIFT / WAFER / DUAL PLATE

SPRING-LOADED / BALL TYPE

HORIZONTAL / VERTICAL INSTALLATION OPTIONS

SIZE RANGE

½” TO 36” (DN15 TO DN900)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

FLANGED / WAFER / LUG / THREADED

SOCKET WELD / BUTT WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

STAINLESS STEEL (SS304 / SS316)

BRONZE / PVC

CARBON STEEL (WCB)

DISC / INTERNALS

STAINLESS STEEL / BRONZE / RUBBER COATED / SPRING-LOADED

METAL OR SOFT SEATED (NBR, EPDM, PTFE)

STANDARDS

DESIGN: API 6D / BS 1868 / EN 12334

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

USED FOR ON/OFF AND LIMITED FLOW CONTROL I N CLEAN, CORROSIVE, OR ABRASIVE FLUIDS COMMON IN OIL & GAS, CHEMICAL, PETROCHEMICAL, AND WASTEWATER I NDUSTRIES I DEAL FOR FREQUENT OPERATION, QUICK SHUT-OFF, AND TIGHT SEALING NOT SUITABLE FOR HIGH-PRESSURE THROTTLING OR THROTTLING WITH SUSPENDED SOLIDS

TYPE

LUBRICATED / NON-LUBRICATED / SLEEVED / JACKETED

ECCENTRIC / EXPANDING PLUG

ROUND PORT / RECTANGULAR PORT

FULL PORT / REDUCED PORT

MANUAL / GEAR OPERATED / ELECTRIC / PNEUMATIC ACTUATED

HORIZONTAL / VERTICAL INSTALLATION OPTIONS

SIZE RANGE

½” TO 24” (DN15 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600 / 900

PN10 / PN16 / PN25 / PN40 / PN63

END CONNECTIONS

FLANGED / THREADED / SOCKET WELD / BUTT WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

STAINLESS STEEL (SS304 / SS316)

ALLOY STEELS / BRONZE / PVC / PTFE LINED

CARBON STEEL (WCB/LCB)

PLUG / INTERNALS

STAINLESS STEEL / ALLOY STEEL / BRONZE

PTFE / TEFLON / RUBBER / METAL-SEATED

CORROSION & WEAR RESISTANCE COATINGS AVAILABLE

STANDARDS

DESIGN: API 6D / API 599 / MSS SP-78 / MSS SP-85

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

USED TO MAINTAIN CONSTANT DOWNSTREAM PRESSURE IN FLUID SYSTEMS COMMON IN WATER SUPPLY, HVAC, STEAM, GAS, AND PROCESS INDUSTRIES I DEAL FOR PROTECTING EQUIPMENT FROM HIGH INLET PRESSURE NOT SUITABLE FOR APPLICATIONS REQUIRING ZERO DOWNSTREAM FLOW OR TIGHT SHUT-OFF UNDER NO-FLOW CONDITIONS

TYPE

DIRECT ACTING / PILOT OPERATED

SPRING-LOADED / DOME-LOADED / PISTON OR DIAPHRAGM TYPE

SINGLE-STAGE / TWO-STAGE PRESSURE CONTROL

HORIZONTAL / VERTICAL INSTALLATION OPTIONS

SIZE RANGE

½” TO 12” (DN15 TO DN300)

LARGER SIZES AVAILABLE

PRESSURE CLASS

ANSI CLASS 150 / 300

PN10 / PN16 / PN25 / PN40

INLET PRESSURE: UP TO 600 PSI (41 BAR)

OUTLET PRESSURE RANGE: 5-250 PSI (0.3-17 BAR)

END CONNECTIONS

FLANGED / THREADED / SOCKET WELD / BUTT WELD / UNION ENDS

BODY MATERIALS

CAST IRON / DUCTILE IRON

STAINLESS STEEL (SS304 / SS316)

BRONZE / BRASS / PVC / GUNMETAL

CARBON STEEL (WCB)

TRIM MATERIALS / INTERNALS

STAINLESS STEEL / BRONZE / BRASS

ELASTOMERS: NBR / EPDM / PTFE / VITON

CORROSION & EROSION RESISTANCE

STANDARDS

DESIGN: EN 1567 / ASSE 1003 / BS EN 805 / MSS SP-80

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

PROTECTS SYSTEMS FROM OVERPRESSURE COMMON IN BOILERS, COMPRESSORS, PIPELINES, AND PRESSURE VESSELS ENSURES SAFETY BY RELEASING EXCESS PRESSURE AUTOMATICALLY USED IN OIL & GAS, CHEMICAL, POWER, AND INDUSTRIAL PLANTS

TYPE

SPRING LOADED / PILOT OPERATED / BALANCED BELLOWS

SAFETY VALVE / PRESSURE RELIEF VALVE / VACUUM RELIEF VALVE

SIZE RANGE

½” TO 12” (DN15 TO DN300)

PRESSURE CLASS

SET PRESSURES FROM 0.5 BAR TO 600 BAR

(7 PSI TO 8700 PSI), DEPENDING ON TYPE

END CONNECTIONS

THREADED (NPT, BSP)

FLANGED (ASME / DIN / JIS)

SOCKET WELD / BUTT WELD

BODY MATERIALS

ALLOY STEELS (E.G., MONEL, HASTELLOY)

STAINLESS STEEL (SS304 / SS316)

BRONZE / BRASS

CARBON STEEL (WCB)

SEAT & TRIM MATERIALS

METAL-TO-METAL / SOFT SEAT (PTFE, VITON, EPDM)

STAINLESS STEEL / ALLOY OPTIONS FOR CORROSION OR HIGH TEMP)

STANDARDS

DESIGN: ASME SECTION VIII / API 520 / API 526

TESTING: API 527

FLANGES: ASME B16.5 / EN 1092-1

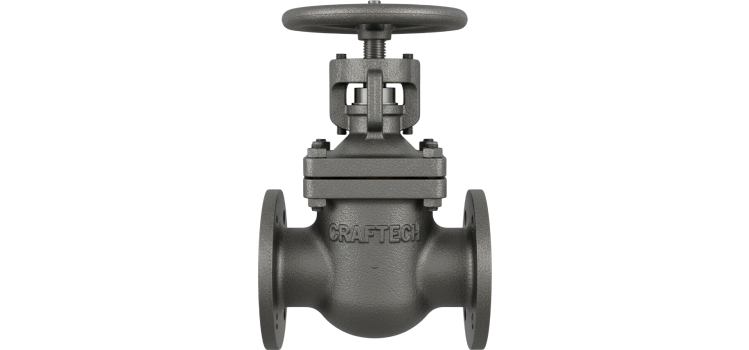

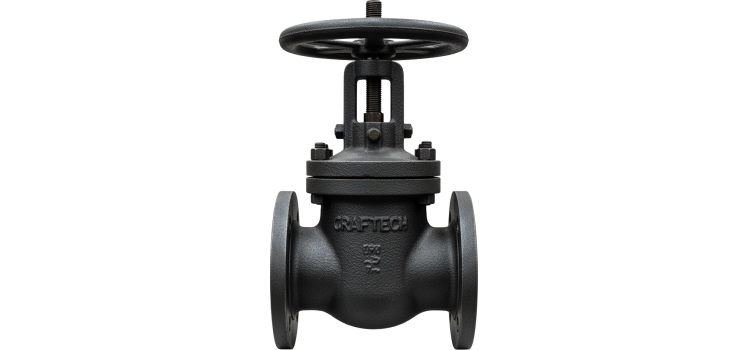

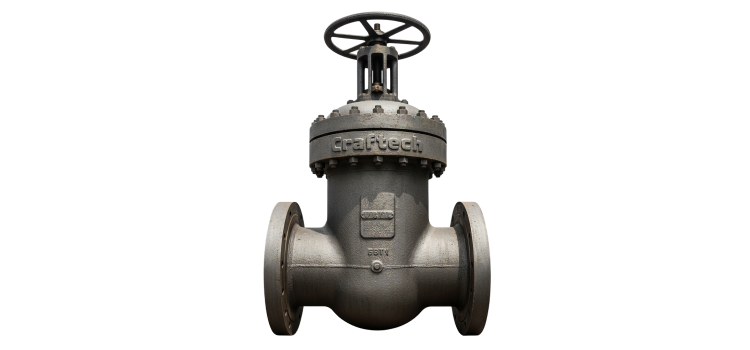

USED FOR ON/OFF CONTROL IN CLEAN OR SLIGHTLY TURBID FLUIDS COMMON IN WATER SUPPLY, WASTEWATER, FIRE PROTECTION, AND IRRIGATION SYSTEMS I DEAL FOR ISOLATION IN PIPELINES WITH MINIMAL PRESSURE DROP NOT SUITABLE FOR THROTTLING OR SLURRY APPLICATIONS

TYPE

RISING STEM / NON-RISING STEM

SOLID WEDGE / FLEXIBLE WEDGE / SPLIT WEDGE / PARALLEL SLIDE

MANUAL / GEAR OPERATED / ELECTRIC / PNEUMATIC ACTUATED

HORIZONTAL / VERTICAL INSTALLATION OPTIONS

SIZE RANGE

2” TO 48” (DN50 TO DN1200)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

FLANGED / BUTT WELD / SOCKET WELD /THREADED / GROOVED

BODY MATERIALS

STAINLESS STEEL (SS304 / SS316)

CAST IRON / DUCTILE IRON

CARBON STEEL (WCB)

BRONZE

WEDGE / INTERNALS

STAINLESS STEEL / BRONZE / GUNMETAL

RUBBER-COATED (NBR / EPDM) METAL OR RESILIENT SEATED

STANDARDS

DESIGN: API 600 / BS 5163 / EN 1074-2 / IS 14846

TESTING: API 598 / EN 12266 / IS 5312

FLANGES: ASME B16.5 / EN 1092-1 / IS 1538

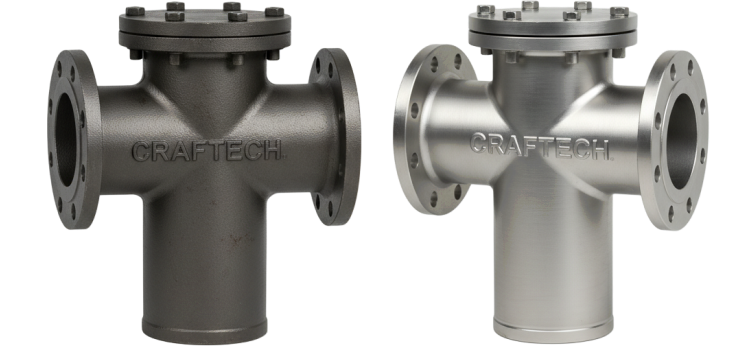

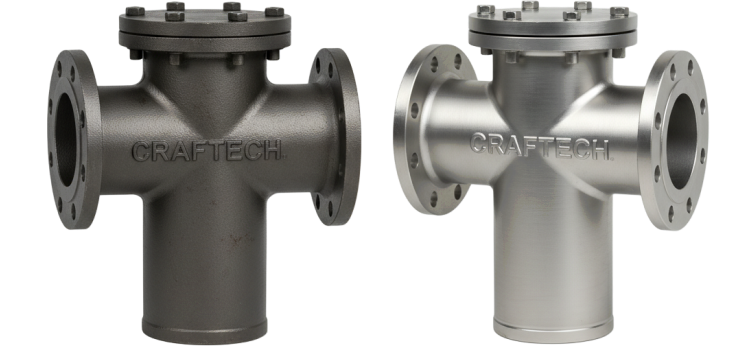

USED TO REMOVE DEBRIS FROM PIPELINES PROTECTS PUMPS, VALVES, METERS, AND INSTRUMENTS COMMON IN OIL & GAS, CHEMICAL, WATER, AND POWER PLANTS I DEAL FOR HIGH-FLOW AND CRITICAL PROCESS SYSTEMS

TYPE

FABRICATED T-TYPE (INLINE) STRAINER

BASKET OR SCREEN TYPE ELEMENT

BOLTED COVER / QUICK-OPENING DESIGN

SIZE RANGE

2” TO 24” (DN50 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

FLANGED (ASME / DIN)

BUTT WELD / SOCKET WELD

BODY MATERIALS

ALLOY STEELS (E.G., MONEL, HASTELLOY)

ALLOY STEEL / DUPLEX / SUPER DUPLEX

CARBON STEEL (WCB)

SCREEN MATERIALS

STAINLESS STEEL (SS304 / SS316)

PERFORATED / MESH / WEDGE WIRE SCREENS

AVAILABLE IN DIFFERENT MICRON RATINGS (e.g. 50–1000 ΜM)

STANDARDS

DESIGN: ASME B31.3 / EN 13445 (FOR PRESSURE VESSELS)

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1

USED TO FILTER DEBRIS FROM PIPELINES PROTECTS PUMPS, VALVES, AND I NSTRUMENTS I DEAL FOR STEAM, GAS, AND LIQUID SYSTEMS COMMON IN OIL & GAS, CHEMICAL, AND WATER INDUSTRIES

TYPE

Y-TYPE (INLINE) STRAINER

BOLTED CAP / BLOW-OFF PLUG OPTION

HORIZONTAL OR VERTICAL INSTALLATION

SIZE RANGE

½” TO 24” (DN15 TO DN600)

PRESSURE CLASS

ANSI CLASS 150 / 300 / 600

PN10 / PN16 / PN25 / PN40

END CONNECTIONS

THREADED (NPT, BSP)

FLANGED (ASME / DIN)

BUTT WELD / SOCKET WELD

BODY MATERIALS

CAST IRON / DUCTILE IRON

STAINLESS STEEL (SS304 / SS316)

CARBON STEEL (WCB)

BRONZE / ALLOY STEEL

SCREEN MATERIALS

STAINLESS STEEL (PERFORATED OR MESH) AVAILABLE IN DIFFERENT MICRON RATINGS (e.g. 50–1000 ΜM)

STANDARDS

DESIGN: ASME B31.3 / EN 13445 (FOR PRESSURE VESSELS)

TESTING: API 598 / EN 12266

FLANGES: ASME B16.5 / EN 1092-1